Quality selection innovation of hulling materials

Release Date: 2022-01-11 Source: Views: 190

App founder Luo Zhenyu in this year's "Friends of Time" New Year speech has such a sentence: If the future will happen, then enter that future first。Under the background of the new era, the era of rice quality upgrade and moderate processing and food saving loss has come inexorably, this issue of "into the quality selection cloud vision" let us walk into Henan to see how to cope with the new "food" generation of Huangchuan Jinfengyuan Grain and Oil Co., LTD.。

Magic quality selection, high content of rough back hulling material sorting

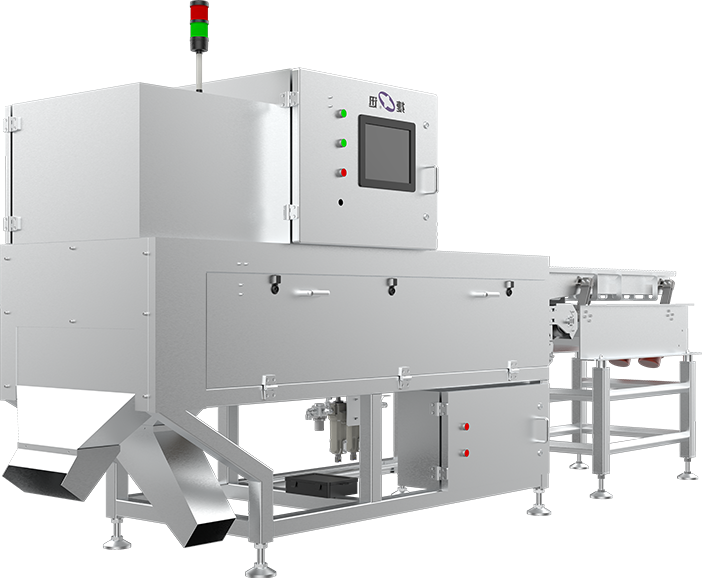

The content of brown rice in paddy hulling is difficult to be effectively controlled and has plagued the rice processing industry for many years. According to the data survey of the main rice producing areas in China, the majority of the paddy hulling materials contain brown rice between 30-70% in the rice processing process, and such a high content of brown rice leads to the high crushing rate of the paddy huller。Some experts from research institutions have found that in many areas, the proportion of broken rice in the hulling section has even exceeded more than 50% of the whole rice processing broken rice. This data is very surprising, and of course, it also brings huge challenges to our moderate processing and grain saving。Liu Daodong, general manager of Huangchuan Jinfengyuan Grain and Oil Co., Ltd. in Henan Province, was deeply touched by this, so the first time to introduce and purchase SF cloud quality sorter to select the quality of husking materials to solve the problem of containing brown rice high in husking materials。The test results show that the husker containing 40-50% brown rice is less than 2% of the husked rice after being sorted by Jexun SF320, which solves the problem of high husker containing brown rice resulting in high crushing rate。

Work together to increase brown rice production simultaneously

In Henan Huangchuan Jinfengyuan Grain & Oil Co., LTD., SF320 Cloud quality sorter has realized that the brown rice content in rice returning is very low, while the sorted brown rice is very clean and directly enters the rice milling section。By adjusting the gravity grain husker return adjustment device, the brown rice output of the rice feeder has been greatly improved. It can be said that a small process point and equipment innovation have brought about a great improvement in the efficiency of the whole production line。

Essence quality, rice koji disease, impurities are not small things

Rice growth process because of weather and other reasons, rice stalk disease will inevitably occur, but different years will be somewhat different, which of course has an impact on the quality of rice processing。In rice processing, the diseased grain of rice that is not completely removed in the cleaning section will be mixed in the back hulls and recycled continuously until it is rolled into small pieces and then enter the rice milling section, thus affecting the processing and quality of the later section。SF cloud quality sorting machine can not only achieve the separation of rice husking, but also "first time" to select and remove diseased rice grains and related impurities in the husking, so as to purify and reduce the load and improve the quality of equipment in the husking section and the back end section。

Science and technology fast, quality choose the future。Jiexun quality selection 6S process promotes the collaborative innovation and development of cloud quality sorting machine and gravity grain rough screen in rice hulling section, and helps the iterative upgrading of the quality of new "food" rice for consumption。More quality selection 6S exciting story, please look forward to the next issue!

App founder Luo Zhenyu in this year's "Friends of Time" New Year speech has such a sentence: If the future will happen, then enter that future first。Under the background of the new era, the era of rice quality upgrade and moderate processing and food saving loss has come inexorably, this issue of "into the quality selection cloud vision" let us walk into Henan to see how to cope with the new "food" generation of Huangchuan Jinfengyuan Grain and Oil Co., LTD.。

Magic quality selection, high content of rough back hulling material sorting

The content of brown rice in paddy hulling is difficult to be effectively controlled and has plagued the rice processing industry for many years. According to the data survey of the main rice producing areas in China, the majority of the paddy hulling materials contain brown rice between 30-70% in the rice processing process, and such a high content of brown rice leads to the high crushing rate of the paddy huller。Some experts from research institutions have found that in many areas, the proportion of broken rice in the hulling section has even exceeded more than 50% of the whole rice processing broken rice. This data is very surprising, and of course, it also brings huge challenges to our moderate processing and grain saving。Liu Daodong, general manager of Huangchuan Jinfengyuan Grain and Oil Co., Ltd. in Henan Province, was deeply touched by this, so the first time to introduce and purchase SF cloud quality sorter to select the quality of husking materials to solve the problem of containing brown rice high in husking materials。The test results show that the husker containing 40-50% brown rice is less than 2% of the husked rice after being sorted by Jexun SF320, which solves the problem of high husker containing brown rice resulting in high crushing rate。

Work together to increase brown rice production simultaneously

In Henan Huangchuan Jinfengyuan Grain & Oil Co., LTD., SF320 Cloud quality sorter has realized that the brown rice content in rice returning is very low, while the sorted brown rice is very clean and directly enters the rice milling section。By adjusting the gravity grain husker return adjustment device, the brown rice output of the rice feeder has been greatly improved. It can be said that a small process point and equipment innovation have brought about a great improvement in the efficiency of the whole production line。

Essence quality, rice koji disease, impurities are not small things

Rice growth process because of weather and other reasons, rice stalk disease will inevitably occur, but different years will be somewhat different, which of course has an impact on the quality of rice processing。In rice processing, the diseased grain of rice that is not completely removed in the cleaning section will be mixed in the back hulls and recycled continuously until it is rolled into small pieces and then enter the rice milling section, thus affecting the processing and quality of the later section。SF cloud quality sorting machine can not only achieve the separation of rice husking, but also "first time" to select and remove diseased rice grains and related impurities in the husking, so as to purify and reduce the load and improve the quality of equipment in the husking section and the back end section。

Science and technology fast, quality choose the future。Jiexun quality selection 6S process promotes the collaborative innovation and development of cloud quality sorting machine and gravity grain rough screen in rice hulling section, and helps the iterative upgrading of the quality of new "food" rice for consumption。More quality selection 6S exciting story, please look forward to the next issue!